Self Drilling Screw

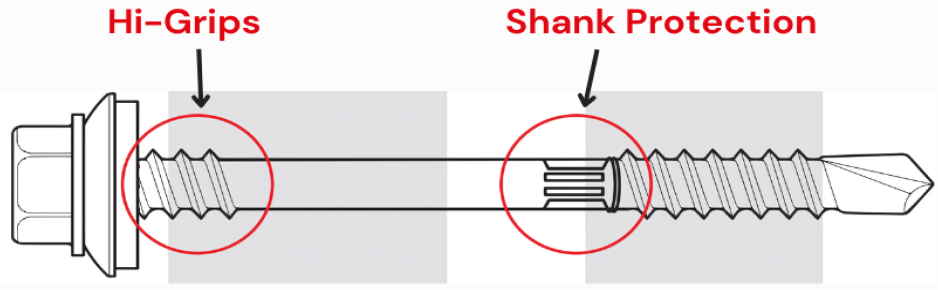

Hi-Grips

Problem

Is there a better way to grip with roof fixing?

Solution

Hi-Grip, which is a secondary thread located at the top of the shank under the washer face. During installation, the washer face carries the fastener in downward motion while the Hi-Grip thread carries the roof profile in the upward motion. The upward pressure tends to straighten or reverse the indent made by the initial penetration and hence obstructing the possibility of water entry.

Advantages of High-Grips

- The operator may feel the thread bite, which is a clear signal to prevent over-drilling.

- Restricts “over-drilling” which leads to ponding or drimpling.

- Prevents sheet moving down the shank when roof is walked on.

- Grips sheet to provide “positive” joint with aluminium bonded EPDM washer.

- Extrudes metal around the fastener hole upwards making water ingress more difficult.

Shank Protection

Problem

There is a hidden danger of under-the-roof corrosion caused by scratching by the roof sheeting along the shank of the fasteners.

Solution

Shank Protection is a revolutionary patented design feature, to protect fastener shanks from scratching and scouring when crest fixing to metal roofing.

Advantages of High-Grips

- Cut a slightly larger hole in the roofing profile than the shank diameter, guarding and protecting it.

- Allow the fastener shank to remain unscuffed and scratch-free during installation, keeping the corrosion coating intact and fully functional.

Screw Category

Class 1

Surface protection: Minimum 5 microns Electroplated

Application range: General internal use, most dry wall and chipboard screws are in this category

| Code | Diameter (mm) | Length (mm) | Drill Capacity (mm) | Drive | TPI |

|---|---|---|---|---|---|

| DX 310 POZ C1 | 6G / 3.5MM | 10 | 2.5 | PHILLIP BIT #2 | 20 |

| DX 312 POZ C1 | 6G / 3.5MM | 12 | 2.5 | PHILLIP BIT #2 | 20 |

| DX 412 POZ C1 | 8G / 4.2MM | 12 | 3.5 | PHILLIP BIT #2 | 18 |

| DX 416 FH | 8G / 4.2MM | 16 | 3.5 | PHILLIP BIT #2 | 18 |

| DX 516 HOZ C1 | 10G / 4.8MM | 16 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| DX 520 HOZ C1 | 10G / 4.8MM | 20 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| DX 525 HOZ C1 | 10G / 4.8MM | 25 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| DX 580 HOZ C1 | 10G / 4.8MM | 80 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| RX 525 HOZ C1 | 10G / 4.8MM | 25 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 12 |

| DX 520 WOZ C1 | 10G / 4.8MM | 20 | 4.5 | PHILLIP BIT #2 | 16 |

| DX 525 WOZ C1 | 10G / 4.8MM | 25 | 4.5 | PHILLIP BIT #2 | 16 |

| RX 525 WOZ C1 | 10G / 4.8MM | 25 | 4.5 | PHILLIP BIT #2 | 12 |

Class 2

Surface protection: Minimum 12 microns Zinc-tin alloy conforming to Class 2 Australian standard 3566

“R” Surface protection: Minimum 17 microns of Ruspert Coating

Application Range: General internal use where significant levels of condensation occurs

| Code | Diameter (mm) | Length (mm) | Drill Capacity (mm) | Drive | TPI |

|---|---|---|---|---|---|

| DX 312 POR | 6G / 3.5MM | 12 | 2.5 | PHILLIP BIT #2 | 20 |

| DX 312 PODR | 6G / 3.5MM | 12 | 2.5 | PHILLIP BIT #2 | 20 |

| DX 412 POR | 8G / 4.2MM | 12 | 3.5 | PHILLIP BIT #2 | 18 |

| DX 412 PODR | 8G / 4.2MM | 12 | 3.5 | PHILLIP BIT #2 | 18 |

| DX 425 FOR | 8G / 4.2MM | 25 | 3.5 | PHILLIP BIT #2 | 18 |

| DX 432 FOR | 8G / 4.2MM | 32 | 3.5 | PHILLIP BIT #2 | 18 |

| DX 416 TW | 8G / 4.2MM | 16 | 1.0 | PHILLIP BIT #2 | 18 |

| DX 520 HO C2 | 10G / 4.8MM | 20 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| DX 525 WOR | 10G / 4.8MM | 25 | 4.5 | PHILLIP BIT #2 | 16 |

| DX 550 WOR | 10G / 4.8MM | 50 | 4.5 | PHILLIP BIT #2 | 16 |

| RX 525 WOR | 10G / 4.8MM | 25 | 2.0 | PHILLIP BIT #2 | 12 |

Class 3

Surface protection: Minimum 25 microns thick Zinc-tin alloy conforming to Class 3 Australian standard 3566

Application Range: General external use in mild and moderate industrial and mild marine applications. The Class 3 is intended for roofing and cladding screw in standard applications.

| Code | Diameter (mm) | Length (mm) | Drill Capacity (mm) | Drive | TPI |

|---|---|---|---|---|---|

| DX 516 HO C3 | 10G / 4.8MM | 16 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| DX 520 HM C3 | 10G / 4.8MM | 20 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| DX 525 HO C3 | 10G / 4.8MM | 25 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| DX 620 HM C3 | 12G / 5.5MM | 20 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 625 HM C3 | 12G / 5.5MM | 25 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 630 HM C3 | 12G / 5.5MM | 30 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 635 HM C3 | 12G / 5.5MM | 35 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 645 HM C3 | 12G / 5.5MM | 45 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 650 HM C3 | 12G / 5.5MM | 50 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 665 HM C3 | 12G / 5.5MM | 65 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 675 HM C3 | 12G / 5.5MM | 75 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 685 HM C3 | 12G / 5.5MM | 85 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| DX 6100 HM C3 | 12G / 5.5MM | 100 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| RX 525 HM C3 | 10G / 4.8MM | 25 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 12 |

| RX 650 HM C3 | 12G / 5.5MM | 50 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 11 |

| RX 665 HM C3 | 12G / 5.5MM | 65 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 11 |

| RX 675 HM C3 | 12G / 5.5MM | 75 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 11 |

| RX 685 HM C3 | 12G / 5.5MM | 85 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 11 |

| RX 6100 HM C3 | 12G / 5.5MM | 100 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 11 |

| RX 720 HM C3 | 14G / 6.1MM | 20 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| SD 626 HO C3 | 12G / 5.5MM | 26 | 8.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 24 |

| SD 638 HWFS | 12G / 5.5MM | 38 | 12.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 24 |

| DX 516 WO C3 | 10G / 4.8MM | 16 | 4.5 | PHILLIP BIT #2 | 16 |

| DX 525 WO C3 | 10G / 4.8MM | 25 | 4.5 | PHILLIP BIT #2 | 16 |

| RX 516 WO C3 | 10G / 4.8MM | 16 | 2.0 | PHILLIP BIT #2 | 12 |

Class 304 Stainless Steel Cap

Head protection: Minimum 300 series stainless steel screw head cap

Application Range: External use in moderate and severe marine environments, classified in accordance with ISO 9223 as generally between 100m from the beach front to approximately 300m inland.

| Code | Diameter (mm) | Length (mm) | Drill Capacity (mm) | Drive | TPI |

|---|---|---|---|---|---|

| SDX 520 HM | 10G / 4.8MM | 20 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| SDX 620 HM | 12G / 5.5MM | 20 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| SDX 650 HM | 12G / 5.5MM | 50 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| SDX 668 HM | 12G / 5.5MM | 68 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| SRX 525 HM | 10G / 4.8MM | 25 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 12 |

| SRX 650 HM | 12G / 5.5MM | 50 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 11 |

| SRX 665 HM | 12G / 5.5MM | 65 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 11 |

| SRX 720 HM | 14G / 6.1MM | 20 | 2.0 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

Class 304 & 410

Surface protection: SUS 304 & SUS 410 Stainless steel

Application Range: Stainless steel screws have weather-resistant properties. This makes them fantastic for creating decks, outdoor furniture, sheds, lawn decorations, and more. They can also be used in areas of high pollution, such as inner cities and near major traffic routes.

| Code | Diameter (mm) | Length (mm) | Drill Capacity (mm) | Drive | TPI |

|---|---|---|---|---|---|

| FDX 416 FH | 8G / 4.2MM | 16 | 3.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 18 |

| FDX 520 HO | 10G / 4.8MM | 20 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| FDX 525 HO | 10G / 4.8MM | 20 | 4.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 16 |

| FDX 625 HM | 12G / 5.5MM | 25 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| FDX 412 PO | 8G / 4.2MM | 12 | 3.5 | PHILLIP BIT #2 | 18 |

| ADX 416 FH | 8G / 4.2MM | 12 | 3.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 18 |

| ADX 625 HM | 12G / 5.5MM | 25 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |

| ADX 675 HM | 12G / 5.5MM | 75 | 5.5 | 5/16″ EXTERNAL HEXAGONAL SOCKET | 14 |